Application of Cryogenic Deflashing Technology

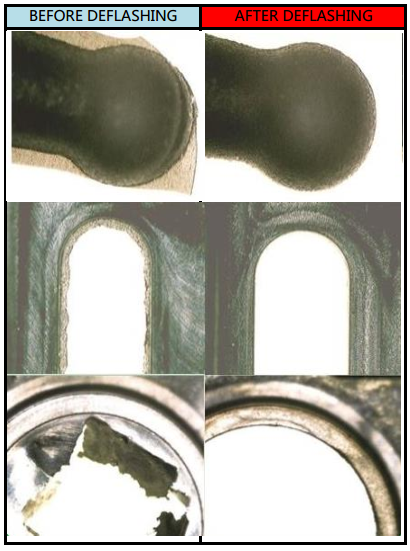

Rubber&Plastic&Die-casting Components Before and After Deflashing

A wide range of molded materials can utilize cryogenic deflashing with proven results. These include:

· Nearly all the rubbers – (including neoprene & urethane)

· Liquid crystal polymer (LCP)

· Silicones

· Precision Plastics – (both thermoset & thermoplastic)

· Glass-filled nylons

· Zinc and Mag die-castings

Examples of applications that use cryogenic deflashing include:

· O-rings, gaskets and other rubber sealings

· Insulators and other electric / electronic components

· Valve stems, washers and fittings

· Short tubes and flexible boots

· Rubber absorbers and bumpers for automobile

· Face masks & goggles

· Mobile phone housing and intelligent watch strap

· Zinc and mag alloys like door lockers for auto cars

.jpg)

Sample Components Suitable for Cryogenic Deflashing Machine