Cryogenic Deburring or Deflashing Machine to remove the rubber washers flashes

Time:2022-01-29

Views:1011

Cryogenic Deburring or Deflashing Machine to remove the rubber washers flashes

Cryogenic deflashing machine is useful and efficient technology to remove the flashes of rubber parts,including the rubber washers.

Cryogenic deburring will have good deburring precision and high efficiency to remove the flashes of washers.

To illustrate well, here i present a good example for you to understand the efficiency of cryogenic rubber deflashing machine.

Part Name: Rubber Washers

Part Weight: 0.12g/pc

Part Material: EPDM/CR

1. Process Result

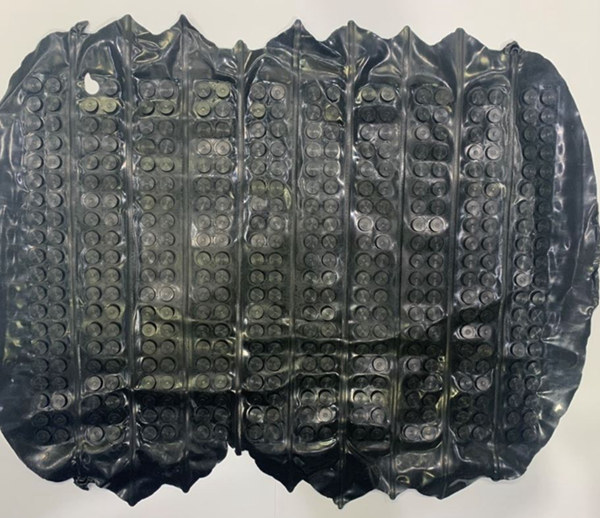

BEFORE DEFLASHING

AFTER DEBURRING

From the photo, you can see that the deburring precision is very good.

2. Process Effciency

If the flashes of washers are thin, thickness less than 0.1mm(flash thickness is very import, should be very thin), then we can have a following process efficiency.

Qty per cycle: 1kg

Cycle time: 6+2.5=8.5mins

Qty per Hour: 7kgs

Qty per Day: 56kg=466666pcs.

You can see that nitrogen deburring machine can have a about 0.5 million rubber wahsers deburring ability, it is of high efficiency comparing with manual deburring/

To illustrate well, here i present a good example for you to understand the efficiency of cryogenic rubber deflashing machine.

Part Name: Rubber Washers

Part Weight: 0.12g/pc

Part Material: EPDM/CR

1. Process Result

BEFORE DEFLASHING

AFTER DEBURRING

From the photo, you can see that the deburring precision is very good.

2. Process Effciency

If the flashes of washers are thin, thickness less than 0.1mm(flash thickness is very import, should be very thin), then we can have a following process efficiency.

Qty per cycle: 1kg

Cycle time: 6+2.5=8.5mins

Qty per Hour: 7kgs

Qty per Day: 56kg=466666pcs.

You can see that nitrogen deburring machine can have a about 0.5 million rubber wahsers deburring ability, it is of high efficiency comparing with manual deburring/