What Effect can Cryogenic Deflashing Technology Bring to You ?

Time:2019-03-01

Views:1952

What Effect Can Cryogenic Deflashing Machine Bring to You?

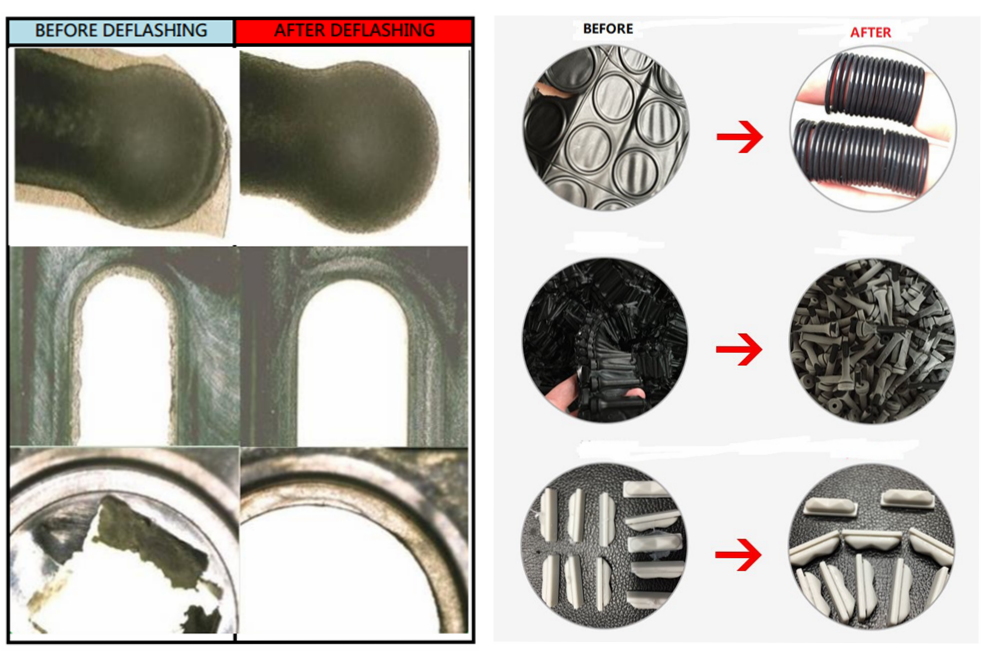

Cryogenic Deflashing Machine is widely used in removing the flashed of small rubber and plastic parts like O-rings, gaskets and other molded parts.

With the cryogenic processing technology, the flashes are firstly frozen and then shot down by the high-speed suitable samll szie projection media (Polycarbonate blast). The surface quality of molded rubber and plastic rubber parts can be improved greatly.

APPLICATIONS

A. O rings, irregular rubber parts with different material and sizes.

B. Micro electronic product parts

C. Precision elastomeric parts

D. Precision injection moulding plastic parts

E. R & D part runs

F. Die casting products, like zinc aluminum, magnesium alloy

ADVANTAGES:

High efficiency: The machine can replace about 60-80 worker to removing the flashes.

High precision: It can remove small and hardened flashes which cannot be removed by handworkers and improve precision of the products.

Low cost: It also has a feature of lower cost comparing with processing the parts by handworkers.

NANJING PEGE TECHNO MACHINE CO.,LTD IS A LEADING CRYOGENIC DEFLASHING MACHINE SUPPLIER&MANUFACTURER IN THE WORLD.